Summary

This principle, known as the 80/20 rule, has become a cornerstone of quality control, process improvement, and business strategy, enlightening and empowering professionals in these fields. This article delves into its origins, Juran’s role in applying it to quality, and several real-world case studies demonstrating its profound impact.

1. The Origins of the Pareto Principle

The concept originated with Vilfredo Pareto, an Italian economist who observed that 20% of Italy’s population owned 80% of the country’s land. Pareto’s insight into unequal distribution patterns extended beyond wealth—it applied to many natural and social phenomena.

. Juran’s Insight: From Economics to Quality

In the mid-20th century, Joseph Juran recognized that Pareto’s observation had profound implications for quality management:

- In manufacturing, a small number of defect types typically account for the majority of quality issues.

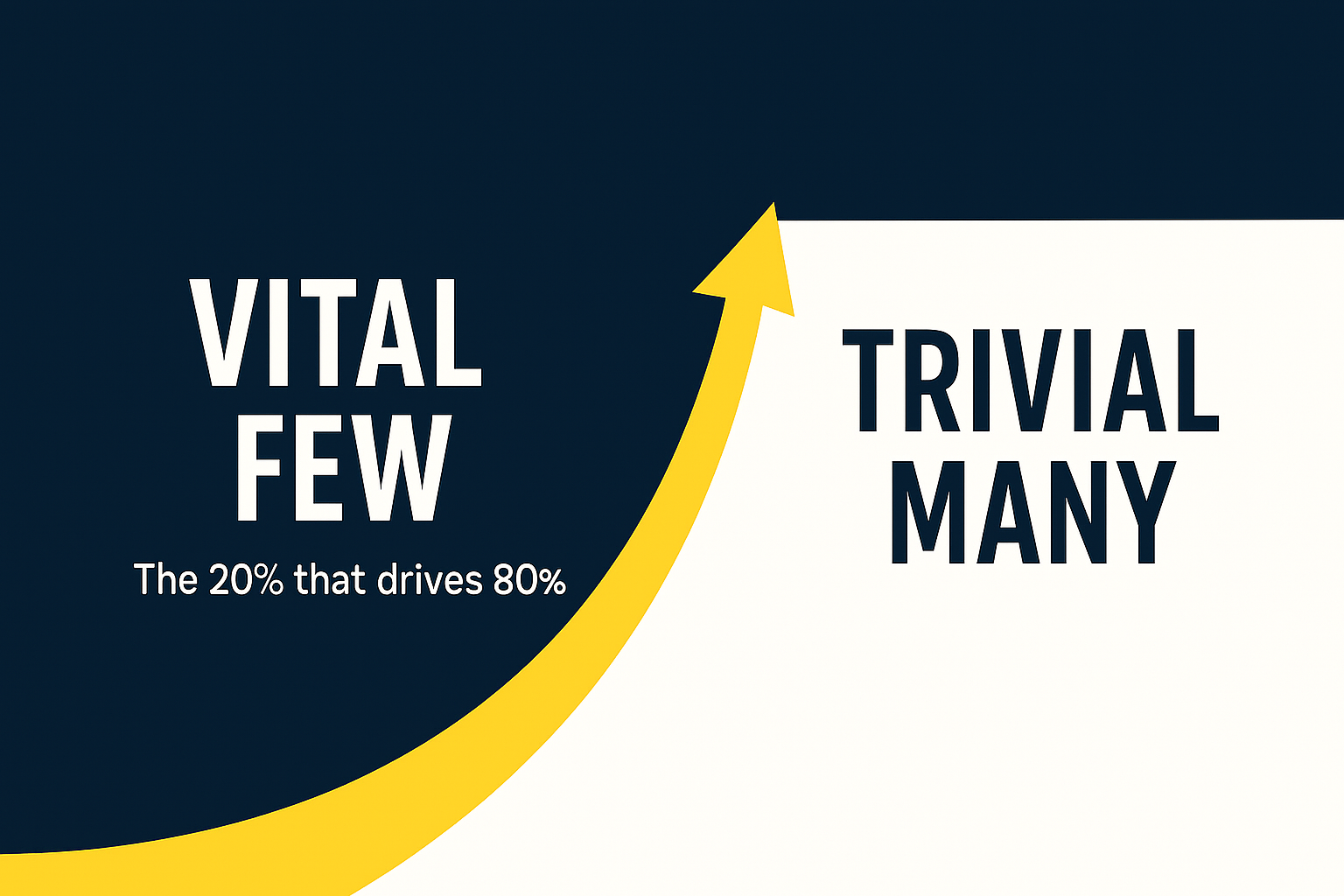

- Juran coined the terms “vital few” and “trivial many” to describe this imbalance. The ‘vital few’ are the small number of causes that contribute to the majority of effects, while the ‘trivial many’ are the large number of causes that contribute to a small portion of the impact.

- He introduced the Pareto Chart, a visual tool to rank causes by impact, helping managers prioritize corrective actions.

3. Why the 80/20 Rule Matters

The Pareto Principle is not a rigid Law but a heuristic—a way to focus resources where they matter most:

- Quality Control: 80% of defects come from 20% of causes.

- Customer Service: 80% of complaints come from 20% of customers.

- Business Strategy: 80% of profits often come from 20% of products or clients.

By identifying the “vital few,” organizations can achieve disproportionate gains with focused effort.

4. Real-World Case Studies

Case Study 1: Motorola and Six Sigma

In the 1980s, Motorola faced increasing defect rates in its electronics manufacturing operations. Applying Juran’s teachings:

- Analysis: Pareto Charts revealed that three defect categories caused nearly 70% of failures.

- Action: Focused process redesign and operator training on those defects.

- Result: Defects dropped dramatically, saving billions of dollars and laying the foundation for Six Sigma.

Case Study 2: Toyota Production System

Toyota applied the 80/20 principle to waste reduction:

- Observation: A small number of process bottlenecks were responsible for most delays.

- Action: Implement targeted Kaizen (continuous improvement) efforts to address those bottlenecks.

- Result: Increased throughput and reduced lead times, reinforcing Toyota’s reputation for operational excellence.

Case Study 3: Amazon Customer Service

Amazon uses Pareto analysis to manage customer complaints:

- Finding: 80% of complaints stemmed from a few recurring issues (late deliveries, damaged packaging).

- Action: Invested in logistics optimization and packaging improvements.

- Result: Significant drop in complaint volume and improved customer satisfaction.

Case Study 4: Healthcare – Reducing Hospital Errors

A U.S. hospital system applied Pareto analysis to patient safety:

- Finding: 20% of error types (medication dosage mistakes, handoff miscommunications) caused 80% of adverse events.

- Action: Introduced electronic prescribing and standardized shift-change protocols.

- Result: Reduced serious medication errors by over 50% in one year.

5. Juran’s Broader Contributions

Juran’s work extended beyond Pareto:

- The Juran Trilogy: Quality Planning, Quality Control, and Quality Improvement.

- Emphasis on management responsibility for quality, not just technical staff.

- Advocacy for continuous improvement and employee involvement.

6 Modern Applications

Today, the Pareto Principle underpins:

- Lean and Six Sigma methodologies.

- Root Cause Analysis in manufacturing and healthcare.

- Data-driven decision-making in business analytics.

Key Takeaways

- The Pareto Principle helps organizations prioritize high-impact actions.

- Juran transformed a statistical observation into a practical management tool.

- Its relevance spans industries—from manufacturing to tech, healthcare, and finance.